- CASTMASTER STITCHING PINS CRACKED

- CASTMASTER STITCHING PINS INSTALL

- CASTMASTER STITCHING PINS PATCH

- CASTMASTER STITCHING PINS SERIES

- CASTMASTER STITCHING PINS CRACK

Available here in a new and vibrant 'Neon Yellow' colourway, which bound to turn heads and create a statement style. Regular fit, take your usual size.

CASTMASTER STITCHING PINS PATCH

Featuring the signature Belstaff silicone patch to the left sleeve. This jacket is not only water repellant and wind resistant, but it also packs away into a bag, making it the perfect outdoor essential for on the move wear. In Cast Iron Cylinder Heads and Engine Blocks Copyright Īdapted from an article written by Larry Carley for Engine Builder magazineĬrack repair has become one of today's hottest topics because good rebuildable cylinder heads for many late model engines are very expensive and hard to find.Quick view Add to wishlist Belstaff Airspeed Down Jacket Neon Yellow Packableīelstaff Airspeed Down Jacket Neon Yellow Packable RRP £425Klarna x 3 or pay in 30 days available.The Airspeed Lightweight Down Jacket by Belstaff is a super lightweight puffer jacket that has aRegular fitting body and fitted shoulders.

So many engine rebuilders are now repairing heads they would have thrown out only a few years ago as unsalvageable. There have always been options for repairing cracks in cast iron. Pinning and furnace welding are both viable options that have long been used to repair cracks and other kinds of damage. But pinning has its limitations, and furnace welding is not something a novice can learn overnight.Ĭrack repair also involves a certain amount of risk.

CASTMASTER STITCHING PINS CRACK

That is why most of the crack repair activity in the past was limited to high cost heavy-duty diesel heads, antique heads or other jobs that justified the time, effort and risk.

CASTMASTER STITCHING PINS CRACKED

CASTMASTER STITCHING PINS CRACKEDīut due to the high cost of many late model heads and blocks, crack repair may be a cost-effective alternative to buying a new or used casting to replace a cracked head or block.Ĭracks in aluminum heads and blocks are relatively easy to repair by TIG welding, but cast iron is much more difficult to weld. That is why pinning has long been the most popular method of repairing small cracks in cast iron blocks and heads. Pinning can repair about 80 percent of all cracks but it can't fix every kind of crack.

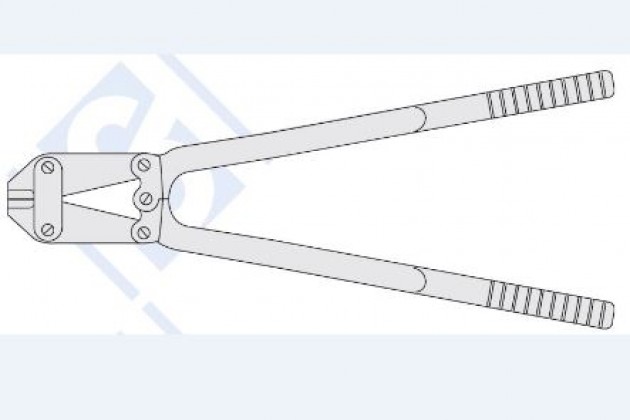

A lot depends on the location of the crack and its severity. Tapered pins with sealer work well on most applications. Welding, on the other hand, restores integrity and allows you to fill cracks and holes. Various types of pins can be used to repair cracks You can even change the shape of the combustion chamber or a port by adding metal. Pinning is the most commonly used technique for repairing cracks in cast iron head, blocks and manifolds because it is fast, reliable and cheap. Pins can also be used to repair cracks in aluminum heads and blocks, too, although TIG welding is often the preferred repair method for aluminum. Pinning is a relatively easy technique to learn and use, does not require much in the way of tools except a drill, guide fixture and tap, and uses no heat.Įssentially, pinning involves drilling holes in a crack, installing overlapping pins to fill the crack, then peening over the pins to seal and blend the surface. There are two basic types of pins: straight and tapered. Each type has its advantages and may work better in certain situations than the other. Tapered pins pull themselves into a crack as they are tightened to provide a tight seal along the entire length of the pin. This occurs because the threads on both the tapered pin and hole have an interference fit. Sealer really is not necessary, but is often used for added insurance. The holes for tapered pins must be carefully hand tapped and the pins hand tightened for a tight seal.

CASTMASTER STITCHING PINS INSTALL

Straight pins are faster to install because an ordinary tap and power drill can be used to install them. Straight pins are designed to twist off when tightened, eliminating the need to cut or grind the heads off (as is necessary with tapered pins). Straight pins also have an interference fit over their entire length, and a tapered shoulder that crushes into the surface. This eliminates a thread line on the surface enabling the surface to be machined. This type of straight pin can also eliminate the need for installing valve seat inserts in cast iron heads. Various types and sizes of crack repair pins and plugs.

CASTMASTER STITCHING PINS SERIES

C Series (CASTMASTER) stitching pins dont spread the crack, in fact they pull the sides of the. Ordinary tapered and straight pins cannot handle certain kinds of cracks, such as those along an outside edge or corner that require support to hold the sides of the crack together. Inside and outside corners are now as easy as flat surfaces. The same goes for cracks in an area of a casting that would open up or pull apart when the casting is under load or gets hot. For these types of crack repairs, locking devices and/or pins with a self-gripping ability can provide the required reinforcement and strength. "Castmaster" pins (manufactured by Lock-N-Stitch) have a unique "spiral hook" or "reverse pitch" thread pattern that grips both sides of a crack when the top shoulder of the pin bottoms against the metal.

0 kommentar(er)

0 kommentar(er)